International Armoured Vehicles

This year, for the first time, Farymann Diesel Engines GmbH was represented at the International

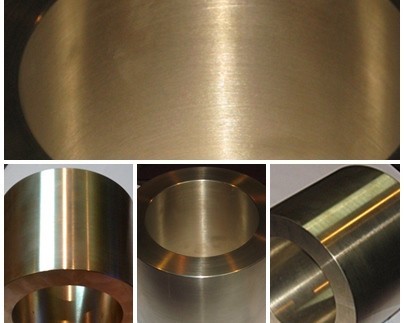

At AGP Farymann, we provide exceptional centrifugal casting services, ensuring each product meets the highest standards of quality and precision. Our dedicated team of professionals is committed to delivering outstanding results, utilizing advanced technology and meticulous attention to detail. We take pride in our craftsmanship and are devoted to meeting the unique needs of our clients with unwavering dedication.

Contact us today to learn how we can support your manufacturing needs with excellence and precision.

AGP Farymann can help you accomplish your goals.

At AGP Farymann, we are proud to offer premium die casting services to our valued customers. With a commitment to excellence and precision, our die casting solutions are designed to meet the diverse needs of various industries.

We understand the unique challenges and demands of our customers and the market. Our dedicated approach focuses on providing tailored solutions that address specific requirements, ensuring efficiency and reliability. By leveraging our expertise and innovative techniques, we consistently deliver products that meet or exceed expectations.

At AGP Farymann, customer satisfaction is our top priority. We strive to build long-lasting relationships by solving our clients’ challenges with dedication and professionalism.

Die casting is one of the most efficient and widely used methods for creating metal parts and components. The process begins by pressing molten metal into mold cavities, or “dies,” under intense pressure. These dies, typically made of hardened tool steel, are precisely designed to shape the target object. Once the metal solidifies, the die is opened to release the cast part. This technology is favored for its ability to produce components with complex shapes, tight tolerances, and clean finishes straight from the mold, minimizing the need for post-processing.

Die casting parts are precision-engineered components created by injecting molten metal into a mold under high pressure. These parts offer exceptional durability, dimensional accuracy, and a smooth surface finish, making them ideal for various industries, including automotive, aerospace, and electronics. Their cost-effective production and consistent quality make die casting parts a preferred choice for high-volume manufacturing.

This year, for the first time, Farymann Diesel Engines GmbH was represented at the International

“My sailboat’s auxiliary engine is a 12 HP, one cylinder Farymann diesel. The boat is

Farymann Diesel Engines GmbH with our Electronics partner Enko Elektroniks launched the new generation Telecom

Copyright 2020. Fary Mann. All Rights Reserved