International Armoured Vehicles

This year, for the first time, Farymann Diesel Engines GmbH was represented at the International

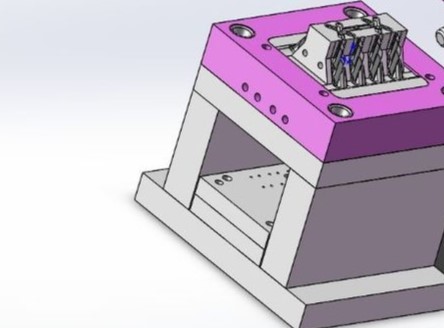

Our injection moulding design approach guarantees precision, functionality, and manufacturability. It begins with concept development and comprehensive CAD modeling, incorporating Design for Manufacturability (DFM) principles to maximize manufacturing efficiency. To anticipate and minimize potential challenges, we select appropriate thermoplastic materials and conduct mould flow analysis. Prototypes are rapidly created and rigorously tested to validate the design. Custom moulds are then crafted and produced to ensure consistent, high-quality results. This meticulous process ensures that each component meets your exact specifications and performs reliably in its intended application.

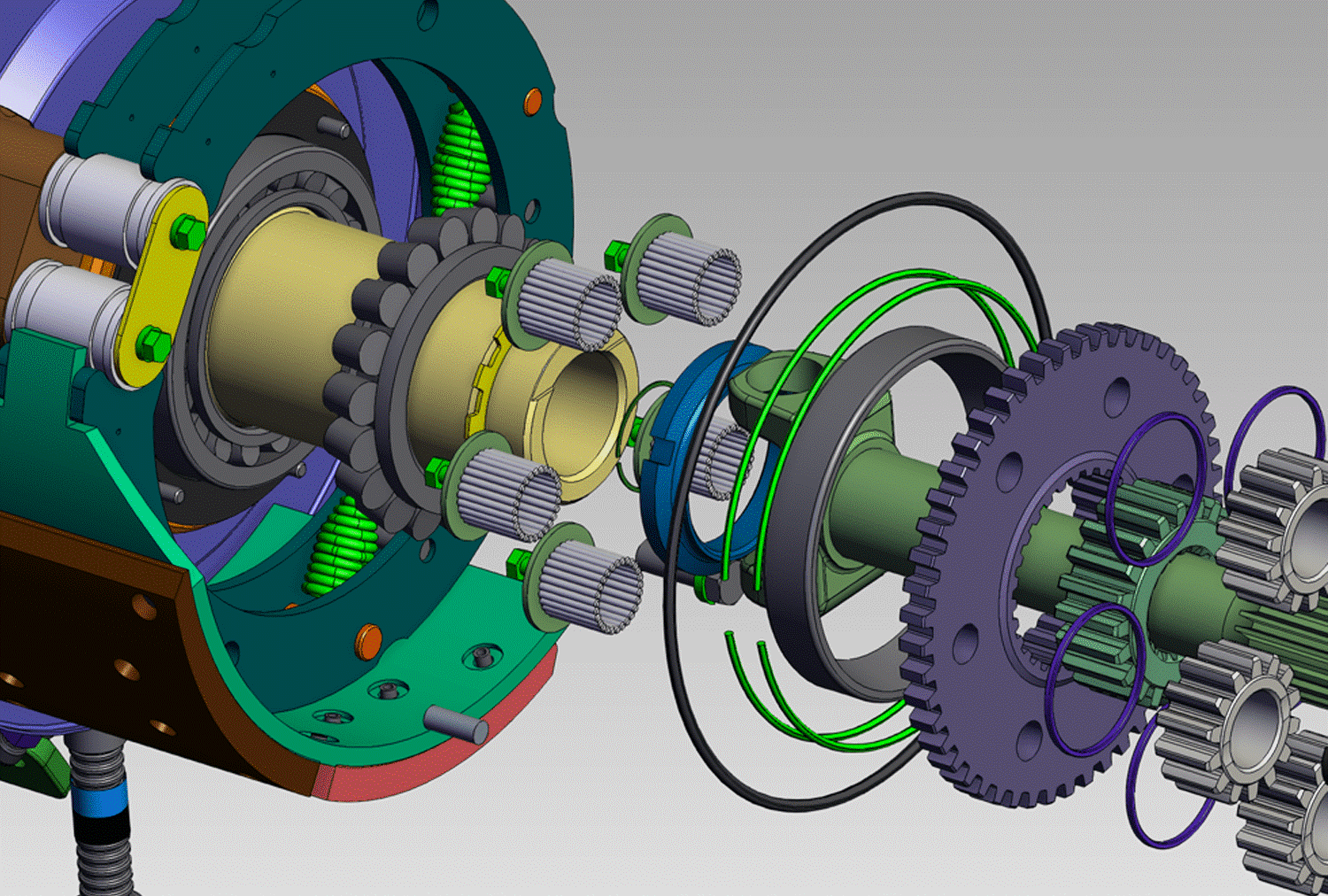

Our professional design team uses cutting-edge CAD software to create precise, realistic models tailored to your specific requirements. We optimize designs for functionality and efficiency by considering material properties, manufacturing techniques, and end-use requirements. From the initial concept and prototype to final production, our comprehensive process ensures that each design meets high-quality standards and aligns with your project goals.

This year, for the first time, Farymann Diesel Engines GmbH was represented at the International

“My sailboat’s auxiliary engine is a 12 HP, one cylinder Farymann diesel. The boat is

Farymann Diesel Engines GmbH with our Electronics partner Enko Elektroniks launched the new generation Telecom

Copyright 2020. Fary Mann. All Rights Reserved